Merry Christmas & Happy New Year!

Closed: December 23rd to January 1st

Closed: December 23rd to January 1st

Showing 49–64 of 80 resultsSorted by popularity

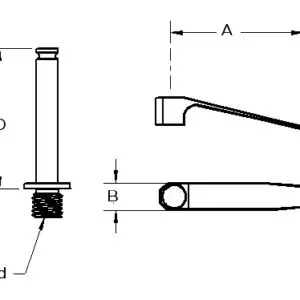

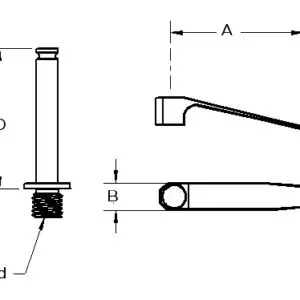

Rubber Tipped Small Tension Spring with 75mm Post and M6 thread

Small Tension Spring with 75mm Post and M6 thread

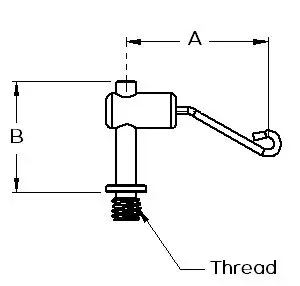

92mm Spring Arm with Plunger and 76mm Post with M6 thread

32mm Wire Tension Spring with 50mm Post and M6 thread

Mini Tension Spring with 50mm Post and M6 thread

Large Tension Spring with 38mm Post and M8 thread

50mm Wire Tension Spring with 50mm Post and M6 thread

82.2mm L bracket with M8 threaded hole located @ 35.6mm & 56.9mm from 25mm bore.

3.235” L bracket with 1/4-20 threaded hole located @ 1.40” & 2.240”mm from 1” bore.

Rubber Tipped Large Tension Spring with 1-1/2” Post and 1/4-20 thread

Rubber Tipped Small Tension Spring with 25mm Post and M4 thread

Rubber Tipped Large Tension Spring with 38mm Post and M6 thread

Rubber Tipped Large Tension Spring with 75mm Post and M8 thread

2” Wire Arm, 1” Post and 1/4-20 thread

92mm Spring with Plunger and 76mm Post with M8 thread

50mm Wire Tension Spring with 25mm Post and M4 thread

Tension springs (also known as extension springs) are spiral coils wrapped tightly together to create tension. When a load is applied to the springs, it spreads the coils apart, which results in resistance of the pulling load. When the load is removed, the coils sling back into their original shape.

Tension springs function as an ideal method to clamp and hold objects, assist in the lifting of heavy objects and disperse the weight of certain loads. The shape, length and thickness of tension springs vary based on their function. Most springs also have hooks, end coils or loops on the end, which are used to attach to an object or component.

Changing the length of the spring, the wire thickness and the coil’s diameter allow users to apply tension springs to an array of applications and loads.

Like most coils and springs, tension springs are constructed from several types of materials to accommodate a particular use. Corrosive elements, temperature and the stress of certain applications determine which type of material manufacturers use to build springs.

Here are a few common uses of tension springs:

A wide selection of springs are available depending on the application and the size of the components. Although they’re cheap and easy to produce and manufacture, extension springs maintain a high level of reliability.

Industrial systems with demanding and extreme environments rely heavily on these springs. Even though they’re available in many variations, the role of all extension springs is to capture and redirect applied force.

Can't find what you're looking for? Fill out our contact form or call us.