A sturdy fixture plate is at the heart of modular fixturing. Choose a thread type and plate design that matches your machine and your project type. These plates are easy to mount and come with a wide range of additional pieces. Simply screw them onto your plate, record their location and use them to hold your workpiece. A modular fixture can be used for high-volume production or to perfect a prototype before creating a solid fixture.

Industry-Leading Quality

For 46 years, Rayco Fixture has been leading the industry in CMM fixtures and custom plates. We guarantee quality products that offer you increased precision, easily repeatable processes and long-lasting durability.

Use our alpha-numeric system to easily track the location of fixture clamps and other accessories to hold components in place. Our precision-ground components use the highest quality of materials and work processes to ensure accurate mounting holes and repeatable designs for your product testing or custom-part manufacturing process.

A poor quality plate leaves room for production error and won’t properly handle complex components. Your CMM equipment can only produce precision components if your workpiece is held securely in place in the exact position required.

Versatile CMM Fixture Plate Options

Select the ideal plate or line of products from our extensive catalog. Thread types options for our plates include:

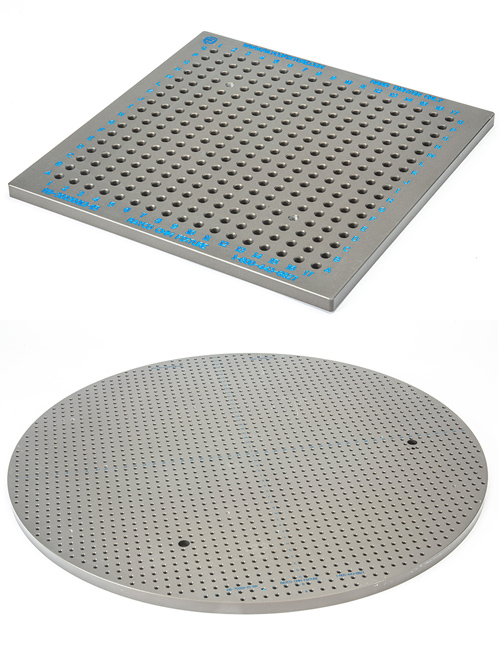

Select an acrylic, aluminum, steel, adjustable or round plate to achieve the optimal CMM fixturing. Our plates can be used in CMM, vertical, or vision applications to produce repeatable results that are easy to alter, adjust and refine. This allows your specialized parts to come out exactly how you want them with repeatable, refinable precision.

Common Applications

Our plates are not only applicable to a variety of projects, but they are also successfully used in a range of industries. Explore the ways you can increase the efficiency of your custom production strategy in your industry with a fixture plate. Here are the industries we’re already proudly serving:

- Defense

- Automotive

- Aerospace

- Medical

- Heavy equipment

- Manufacturing

- Machining

Because of the customizable nature of modular fixturing, any manufacturing or product design application that uses CMMs. Discuss your particular production needs to see how you can accelerate your setup process with a quality plate.

What Are Threaded Holes?

Every fixture plate that we manufacture is made from cast aluminum and features evenly-spaced threaded holes throughout the plate’s surface.

In threaded fixture plates, you attach components to the threaded holes, which are also sometimes referred to as through holes or blind holes. When your fixture plate is not in use, you typically insert screws into the holes for protection.

Rayco’s CMM plates feature alpha-numeric engraving along the outer perimeter of the fixture plate. This allows machine operators to easily find and document threaded hole locations on the plate, which ensures fast and repeatable setups.

What Are Mounting Holes on Fixture Plates?

Threaded grid holes on CMM fixture plates are not the same as mounting holes. At Rayco, all of our fixture plates come with threaded holes, but we can also customize your plates to include mounting holes. A CMM fixture plate with mount holes works in conjunction with angle plates to ensure precise workpiece mounting for highly repeatable and accurate setups.

Contact Rayco Fixture Today

Explore the benefits of using a CMM fixture plate to accelerate your production facility. Learn more about our product line and how you can use it for prototype or one-time-job manufacturing. Ask about ways we can customize your product to match your industry and upgrade your plate with additional accessories to take on even more custom projects.