Merry Christmas & Happy New Year!

Closed: December 23rd to January 1st

Closed: December 23rd to January 1st

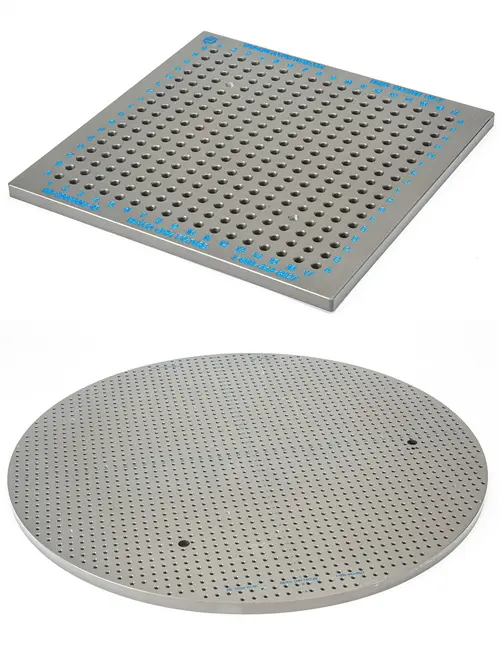

Also known as module fixture plates, an aluminum fixture plate plays an integral role during many diverse manufacturing processes. Plates contain an abundance of threaded holes, into which parts can be mounted. This ensures greater convenience and time-savings while working, which will keep your customers satisfied with their experience.

Tooling plates can be custom-designed to suit specific applications. This makes them extremely valuable within CNC machining, which often requires use of specially designed parts and components.

Along with keeping parts and components safe, tooling plates can also help create a more efficient manufacturing process. Plates can be designed with numbers and letters printed on them, and these numbers and letters will then correspond to a specific part or component for easy retrieval.

Fixture plates are also known for their affordability. When it comes to custom jobs, they are designed to be disposable. That means you can use them for specialized tasks and projects without any worries about your budget.

Precision is a must when it comes to certain applications, such as CNC machining. While basic t-slot tooling can be used to create parts and components, this system leaves a lot to be desired for certain applications.

For example, installation and measurement must be performed manually when using t-slot tooling. That means you must continually re-program machines throughout the process. Thanks to advances in machining computers and equipment, having a streamlined process can make a huge difference in your productivity.

In that case, fixtures plates only require one-time programming. The numerous steps associated with t-slot tooling are no longer a factor. Not only does this save you time on projects, it also ensures a more precise finished product.

Additionally, you can rest assured that the fixture will be oriented and proportioned correctly for the specific application. You’ll also wind up with a cleaner edge on the part, which reduces worries about chips. A chipped edge can dissatisfy your customers, while also calling for a redo on the finished product.

The fine-grain aluminum alloy used to create tooling plates enhances internal stability greatly. You can look forward to minimal movement and stress while machining, which is a must.

Aluminum also holds up well against rust and corrosion. This removes the need for a protective treatment over the plate, which is required with other types of tooling procedures. Again, tooling plates remove the necessary steps associated with other process.

These plates are incredibly machinable thanks to their many inherent characteristics. You can expect minimal distortion, as well as unbeatable surface flatness when required.

Tight tolerances can also be achieved, which means components will exhibit minimal variation. This is a must to ensure all components are machined to the exact specifications stated. With precision parts, you know your customers will be completely satisfied with the work performed.

Aluminum tooling plates are also known for their versatility. An aluminum fixture plate can be combined with painting, powder coating, and anodizing to best meet your needs.

The quality of the tooling plates used for an application also make an impact on the finished product. Fortunately, Rayco Fixture features a variety of tooling plates, including:

These plates featuring engraving, with numbers listed on the X-axis and letters listed on the Y-axis. They are clear hard lube anodized, and can even be designed with optional CMM mounting holes. Weight is 240 ounces, dimensions are 12 × 12 inches, and thread type is 1/4-20. Plate shape is square, while length and width are 12 inches.

The R20-66375-50 is also engraved, with numbers on the X-axis and letters on the Y-axis, as well as clear hard lube anodization. Weight is 32 ounces, dimensions are 6 × 6 inches, and thread type is 1/4-20. Plate shape is also square. Length and width are 6 inches.

Like the R20-121250-50, this plate includes engraved numbers on the X-axis and letters on the Y-axis, is clear hard lube anodized, and can be outfitted with optional CMM mounting holes. Weight is 240 ounces, dimensions are 11.81 × 11.81 inches, and thread type is M8, with a square plate shape. Length and width are 300 millimeters.

Along with the optional CMM mounting holes, engraved numbers and letters and clear hard lube anodization are also included. Weight is 432 ounces, dimensions are 18 × 18 inches, and thread type is 1/4-20. Plate shape is square. Length and width are both 18 inches.

R6-60060013-15

Engraved numbers and letters, clear hard lube anodization, and optional CMM mounting holes are also included with the R6-60060013-15. Specs include dimensions measuring 23.62 × 35.43 inches, square plate shape, and M8 thread type. Length is 600 millimeters, while width is 900 millimeters.

The R8-75075019-15 model is equipped with clear hard lube anodization, engraved numbers on the X-axis and letters on the Y-axis, and the option of including CMM mounting holes. Weight is 1,232 ounces, dimensions are 29.53 × 29.53 inches. The thread type is M8, plate shape is square, and the length and width are 750 millimeters.

Along with the numerous benefits listed above, tooling plates also have a wide range of applications across many diverse industries:

While the above industries are definitely distinct from one another, what they have in common is a need for precisely rendered parts and components. These parts must be made to the exact specifications of the piece of equipment or machinery they’re being used in.

Their ability to be easily customized for so many applications makes it easy to see why aluminum tooling plates are so valuable for a wide range of industrial uses.

Modular fixturing allows convenient customization of work holders. Customization is a crucial component when it comes to specialized and unique applications.

Among the many work holding options available, modular fixturing is ideal for one-of-a-kind projects that aren’t typically repeated. They sit somewhere between permanent, special purpose fixturing and general purpose applications.

These systems can utilize a variety of components and elements for detailed customization. When it comes to one-time applications, their economical nature make them an ideal option. The same can be said of repeat but infrequent applications. With modular fixturing, you can affordably perform infrequent and one-off runs with confidence that the end product will be up to par.

Many companies also offer made-to-order components to their customers. While customers appreciate this level of service, it can also be expensive for companies to complete such orders. Modular fixturing makes it possible, which ensures you can build lasting relationships with your customer base as you continue to meet and exceed their expectations.

Other good uses of modular fixturing include trial order runs, prototypes, and as a temporary solution while a permanent fixture is being serviced. That way you never have to deal with costly downtime.

If you use modular fixturing at your business, you must have the right aluminum tooling plate at your disposal. These plates are a key component of modular processes, and without them, you would be unable to complete many specialized jobs and projects.